Made some more progress on the NoDiz project.

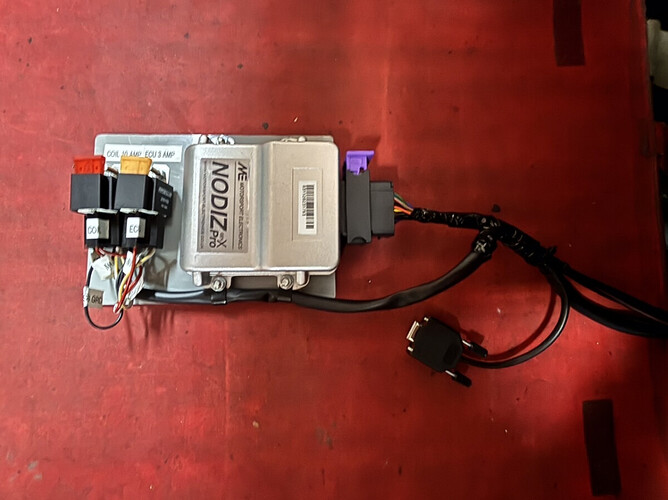

Here is the wired ECU with two power supply relays. I installed separate relays for the ECU power supply and the coil pack power, which is already run within the NoDiz loom to the ECU connector block area, so a relay seemed to simplify things.

I used a direct +12v battery connection bus that was already available under the bonnet, right or passenger side. I already had added a 11 pin block connector in this area to accommodate previous electronic ignition installations.

The connector already has a very stout ground that runs back to the main ground bus on the right side dash mount, a couple of ignition wires that are now used to trigger the power relays and power the Wideband O2, a tach signal wire back to the refurbished Smiths tach, and some vestigial wires for the stock coil and dizzy. The stock security switch is long gone from my car.

As mentioned previously, I am using a fully terminated Zetec loom. The individual loom runs are too long for my installation, so unfortunately every run requires shortening. I would recommend trying to get a fly lead version of this loom and request they include any additional runs you want along with the appropriate connectors. Worth a shot but I don’t see this option directly offered on the Motorsports Electronics web site.

The loom is of very high quality, with individual runs inside plastic coverings. There is approximately 4” loose length of all the plug wires next to the ECU block connector (after easily unwrapping some non-adhesive loom tape) which provides easy access to the female pin receivers in the block connector (after un-clipping the back of the block connector and moisture barrier). The instructions indicated the new crimped pin receivers on the shortened conductors can be pushed through the flexible moisture barrier, but I found it easier to draw each raw wire through the gasket and then perform the crimps.

Using this method I shortened the three conductors to the coil pack, three new conductors to the TPS (should have specified this leg be added to the Zetec loom), and the unwrapped chassis loom wiring for power, ground, tach signal, Wideband O2 signal. Pin A6 (Black) is used for sensor grounds, which in my application included the Wideband O2 data pair (data wire routed to the dedicated A2 Inlet Air Temperature Sensor) and the TPS ground.

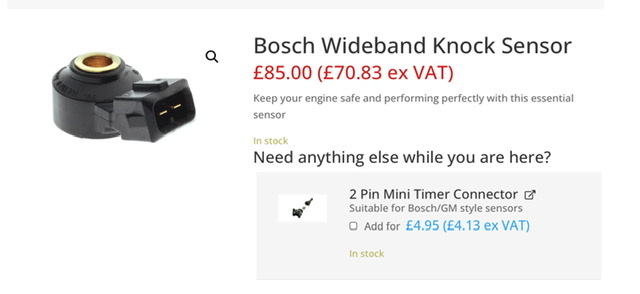

The exception is the CPS, which is two conductors within a grounded shield. The grounded shield shares pin B7 with the Serial RS232 ground, which makes shortening this run difficult at the ECU connector block. I used an easier approach and purchased a new CPS connector and shortened the other end. Note this is really easy because the ground shielding is just stripped back to expose the two conductors that are simply crimped to the standard pin receivers. The ground shield is not attached to the CPS connector. I don’t have the exact call up for the two pin receivers, but they should be very easy to source as a Mini Timer connector, saving the cost of a whole new connector. They are the same pin receivers as used on the Webcon TPS connector. The CPS connector has integrated moisture seals that can be reused with care.

I also made up a matching 11 pin connector that accommodates the original points and coil without too much fuss. Plan is to have the stock stuff in the boot.

I had to further modify the coil pack mount a bit. Once I fitted the spark plug leads I was fouling the carb intake runners. Note my engine is non-standard so may have somewhat different clearance in this area. At any rate, I removed the 1/2” spacer bar noted above, modified the packing washers, and re-drilled the coil pack mount, which lowered the mount away from the block. Unfortunately this caused some interference with the Plus 2 heater hose run, which is very difficult to access with the engine in place. The main point is it is pretty much essential to have the radiator out of the way, but I have not had to remove the carbs to get it sorted.

Next steps are to re-assemble the cooling system, check everything over, and try to start her up. I also still need to download the ECU software to our ancient laptop and connect the supplied USB to serial adapter. After initializing the TPS range, the biggest step is to set the timing of the CPS, which is individual for each installation. Apparently there is a zero advance setting in the ECU to make this one time procedure really straightforward. From then on the ignition map is all digital, and the base map is anticipated to be close enough to run the car.

I have got a promising lead on a local dyno shop for final tuning if required. A friend has his stock Weber Plus 2 in for a session now, so we will see how that goes, but at least we know the car will fit the rollers and they do a lot of carb setups.

So the main takeaway from this update is to have everything you can think of to hand before starting the installation. This included in my case the custom plug leads, CPS connector or pin receivers, wiring strategy into your car, correct TPS connector (mine was supplied with the Webcon TPS bracket and sensor), the firewall grommet, Wideband O2 connectors and the two sizes of pin receivers for the ECU block connector and some miscellaneous loom tape and plastic shielding. A top tip is to have extra pin receivers to hand as it is easy to miss-crimp one without practice to make sure of the required crimper.

I should add the ECU also has provision for driving an electric cooling fan relay and a fuel pump relay. If I were installing the NoDiz in conjunction with a full rewire I would probably use these features and centralize everything in the revised relay and fuse boxes. I already have an aftermarket fan controller and an electric fuel pump installed, so will leave as is. Keep in mind adding additional sensors could require additional conductors on the sensor ground pin A6, so plan accordingly.

Other features not required for our cars include launch control, cam position sensor, and knock control.

Hopefully we are up and running shortly.