It all started as long ago as August 1964 when we had the Elan on road test. I took it home for the weekend and found that & was, in almost every way, the sports car I’d been looking for since i started driving. Then the coupé appeared at Earls Court last autumn and this made it look even more attractive and much more practical. It became the sort of car in which you could reasonably contemplate ine prospect of 20,000 miles business motoring a year. Or could you? Would it be reliable. waterproof, easy to maintain and service?

Would it do 3.000 mile Continental journey* without attention and, on the other hand would it object to motoring just in and out of London for a week.

Well, 12,000-mlle tests are designed to answer questions like this and to cut along story short, a coupá was ordered early this year. Most people buy their Elans in lkit form and bulld them and we thought that we really. ought to go through this part of the exercise as well to make the whole thing representative.

Lotus claimed that it could be assembled in about 25 man-hours but, in spite of what their manufacturers say, know that assembly times for some other kit-car are best measured in man years. So that was the background-apart from soothing our near apologetic transport manager who had never before been relused delivery of a car until our cheque was safely lodged in the bank.

The Elan-builder need never suffer from loneliness–it began to emerge that an amazing proportion of my friends regard themascives as potential owners or builders. Here, they saw, was a splendid opportunity to find out what it was all about, and off they went to assemble their toolkits in preparation.

Friday, March 25

Rang Lotus to give delivery instructions.

“By the way”, they said casually, “will there be somebody there to help ofload it?”

"How many people do you need?*

“At least four.”

"How many do you send with the van?

“Just the driver.”

Thursday, March 31

8.30 a.m. Assembled powerful labour force comprising self, two wives only one of them mine) and Denis Jenkinson, The Elan arrived punctually in the form of engine and gearbox, front suspension, exhaust system, radiator assembly, five wheels and tyres, and numerous other oddments inside the van, followed closely by a trailer with the rest-namely completely trimmed and upholstered, painted and wired body/chassis unit with final drive and rear suspension fitted. After tentative lifting trials on the latter, the company was reinforced by three powerful builders, the rear wheels were fitted, and the whole thing wheeled into the garage like a hand cart and supported under the front by a wooden box. The other parts followed (three people to carry the engine and gearbox), and the whole lot was locked away.

Saturday, April 2

Examined the bits and picces and then went shopping for engine and gearbox oils and brake fluid. Decided that hoisting the power unit up by the roof beams could bring about the total collapse of the garage. Since new garages are not accepted without question on the weekly expense sheet, a detachable wooden portal frame of 4 x 2 was designed and made to support the block and tackle. Enter helper No. 1 (Farnborough scientist, inveterate special builder, owner of Rochdale Olympic, Triumph 2000, VW) arisen from his sick bed to see what was going on. While the gearbox was lying accessibly on the floor it seemed a good idea to fil it–this was the biggest mistake we made and accounts for the garage later becoming a sort of oily hole of Calcutta.

Work was now suspended in favour of reading Section R. of the Workshop Manual “Overhaul and Rebuild Instructions” or how to fix your remaining bits on to a new body/chassis unit after writing off the old one. This is a very helpful document apart from a few idiosyncracies like the fact that it advises you to start with the body raised on trestles and only lower it to the floor when it’s finished. We didn’t have any trestles and we couldn’t think how to lower a 14 cwt. car wthout sawing through the legs.

Sunday, April 3

8.30 a.m. Arrival of the Motor photographer and ceremonial laying out of components.

10 a.m. Enter helper 2 (surveyor, Lotus Eite, Mini Cooper S. Allia)

10.40 a.m. Official opening of work. Front hubs, brakes. coil spring/damper units and anti-roll bar were bolted on and the track-rod ends and brake hoses connected. No problems here except the immense variety of spanners you seem to need and the tedium of inching stiff Nyloc nuts down long threads.

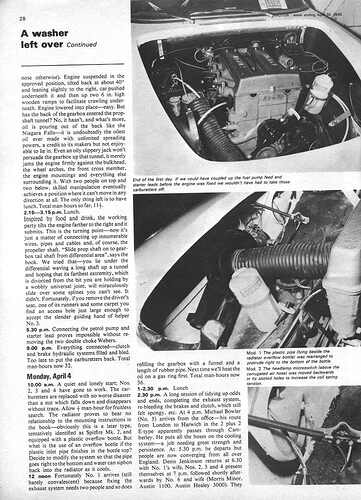

11.30 a.m. Helper No. 3 arrives (another Farnborough bollin, self-constructed Herald Climax). Starter and gear, lever removed from power unit. Portal frame erected inside garage and nailed securely in place–block and tackle lashed to it with best nylon tow rope-slings put round engine using second best nylon tow-rope.

12.30 p.m. Helper No. 4 (general manager of a transport fleet-DB4GT, Westminster, Mini) comes hot foot from the golf course. Elan lowered to the ground after putting on the front wheels (because the garage isn’t high enough to hoist the engine over the nose otherwise). Engine suspended in the approved position, tilted back at about 40» and leaning slightly to the right, car pushed underneath it and then up two 6 in. high wooden ramps to facilitate crawling underneath. Engine lowered into place- easy. But has the back of the gearbox entered the prop-shaft tunnel? No, it hasn’t, and what’s more oil is pouring out of the back like the Niagara Falls-it is undoubtedly the oilest oil ever made with unlimited spreading powers, a credit to its makers but not enjoyable to lie in. Even an oily slippery jack won’t persuade the gearbox up that tunnel, it merely jams the engine firmly against the bulkhead, the wheel arches, the front cross member. the engine mountings and everything else surrounding it. With two people on top and two below, skilled manipulation eventually achieves a position where it can’t move in any direction at all. The only thing left is to have lunch. Total man-hours so far, 11 1/2.

215-3.15 p.m. Lunch.

Inspired by food and drink. the working party tilts the engine farther to the right and it submits. This is the turning point - now it’s just a matter of connecting up innumerable wires, pipes and cables and, of course, the propeller shaft. "Siide prop shaft on to gearbox tail shaft from differential area’’ says the book. We tried that-you lie under the dilTerential waving a long shaft up a tunnel and hoping that its farthest extremity, which is divorced from the bit you are holding by a wobbly universal joint, will miraculously slide over some splines you can’t sec. It didn’t. Fortunately, if you remove the diver’s seat, one of its runners and some carpet you find an access hole just large enough to accept the slender guiding hand of helper No. 3,

5.30 p.m. Connecting the petrol pump and starter lead proves impossible without removing the two double choke Webers.

9.00 p.m. Everything connected-clutch and brake hydraulic systems filled and bled Too late to put the carburetters back. Total man-hours now 32

Monday, April 4

10,00 a.m. A quiet and lonely start Nos. 2. 3 and 4 have gone to work. The carbureters are replaced with no worse disaster than a nut which falls down and disappears without trace. Allow 4 man-hour for fruitless scarch. The radiator proves to bear no relationship to the mounting instructions in the book obviously this is a later type tentatively identified as Spitfire Mk. 2. and equipped with a plastic overtiow botte. But what is the use of no overlow bottle if the plaste malet pipe finishes in the bottle top!?

Decide to modily the system so that the pipe goes right to the bottom and water can siphon back into the radiator as it cools.

12 noon Fortunatoly No. 1 arrives (still barely convalescent) because fixing the exhaust system needs two people and so does refiling the gearbox with a funnel and a length of rubber pipe. Next time well heat the oil on a gas ring first. Total man hours now 36.

1-2.30 p.m. Lunch

2.30 p.m. A long session of tidying up odds and ends, completing the exhaust system. re-bleeding the brakes and clutch, which sull felt spongy, etc. At 4 pm. Michael Bowler (No, 5) arrives from the office - his route from London to Harwich in the 2 plus 2 E-type apparently passes through Cam Berkeley. He puts all the hoses on the cooling system - a job needing great strength and persistence. At 5.30 p.m. he departs but people are now converging from all over England, Denis Jenkinson returns at 6.30 with No. 1’s wife. Nos. 2, 3 and 4 present themselves at 7 p.m. followed shortly afterwards by No. 6 and wife (Morris Minor, Austin 1100. Austin Healey 3000). They both realize they’re No. 6 - they only know they’ve been invited to dinner that evening.

745 p.m. Useful man-hours now 44. There are now 12 people assembled and is is getting dark. We decide to abandon tedious pursuits like tightening the front suspension in favour of the spectacular gesture of starting the engine to entertain the admiring audience. Before switching on ignition, the book says, “press starter solenoid and turn engine over until oil pressure shows on dail.” That bit was all right. "Ignition can now be switched on and engine started " This proved optimistic - so the investigation began!

There is no fuel in the filter bowl - Obviously, the pump wasn’t priming, so the thing to do was to pour petrol in the filter chamber. It would soon prime when the engine was running. It started and ran until the float chambers were empty again but still there wus no petrol feed. People drove off in all directions to buy more petrol, the back of the car was raised until it looked like a dive bomber-still no fuel Only one thing to do now --stuff up the vent pipe in the tank and pressurize it by blowing into it. But no one present could possibly get their mouth round the quick filler orifice so an apperatus of large sorbo washers and rubber tubes was manurfctured.

That did it. One powerful blow down the tube, the sides of the tank bulged and twanged and there was a rushing noise as several galons al petrol poured an to the garage floor The viewers regarded each other with a wild surmise, removed the boot floor as one man and a tank surrounded by liguid petrol was revealed with a naked outlet pipe connected to nothing at all.

Afer this it ran better. Apparently, there were no oil, water or fuel leaks.

9.30 p.m. We decided to call it a day. An orgy of carbureter adjustment had wetted up to rear plugs, dinner and guests had been ready since 8 a.m. and both were it retrievably ruined. All the alcohol remaining In the house alter the previous night had been consumed by hungry wives. Would Temple Press regard this as a legitimate constructional expense? Total man-hours confused - total useful man-hours, let’s be kind and say 44 1/2.

A singularly Il-timed announcement by the Ford Motor Go. (see last week’s Motor) now chained the technical editor to his desk.

Good Friday

Just odds and ends left now, Finish tightening up the rest of the front suspension, clean and roast two plugs in the gas oven, tighten all the wheels, adjust the handbrake calipers to give 3 thou, clearance between the pads and the discs, and fasten on the number plates and the licence disc. Then the front wheels had to be adjusted to ??-in. toe-in (instead of about 2-in, toe-in) which involved the design and construction of the Bulmer Tracking Gauge from a 6 ft. length of 4 x 2, two wooden uprights, two inward pointing bolts in push fit. wooden holes and four nails–guaranteed reliable and free from optical errors.

Finally, a second and more successful adjustment of the carburetters (becoming more expert now) and the installation of the rest of the inlet air box and cold air trunk. With the aid of faithful helper No. 2 (after lunch) all this added another 11 man-hours (I don’t know why it took so long) making a Grand Total of 55 1/2 man-hours in three working days. So it took us twice as long as it should but we’ve got all sorts of excuses for that. There’s the magnificently high standard of workmanship and, of course, there’s all the thinking time that got included - four people can’t think as cheaply as one.

7:30 p.m. First, second and third trial runs (because Nos. 3 and 4 had assembled as well by now). At this stage the technical editor abandoned the role of builder and assuming the guise of customer, took delivery of the car for himself.

Faults on delivery

- Headlamps flickered on and off while driving at night with a fluttering noise from the relay

- Indicator warning light not working

- High frequency rattle inside nearside door.

- Wind whistle from nearside door.

Everthing celse worked perfectly. Five minutes study of the wiring diagram indicated that Fault 1 could only be caused by the micro-switch which completes the circuit when the lamps are raised; it is pulled on by a tension spring attached to the bottom of the pivoted offside lamp case. Moving the switch 1/8 in. farther away on its slotted mounting increased the spring force enough to cure the trouble. Funnily enough. a whole page of the handbook is devoted to possible headlamp faults but this isn’t one of them.

Popular questions

I can now forecast that everybody I meet will ask some of the following questions:

- Knowing where the car was going, do you think that Lotus put it together, made sure everything fited and then dismantled again? If they did, they made a jolly good job of re-painting all the holes, touching up the scratches and replacing everything that could show assembly marks.

- Does water leak into the body? Not yet and It’s rained or snowed almost unceasingly since i was finished

- Were there any parts missing? No.

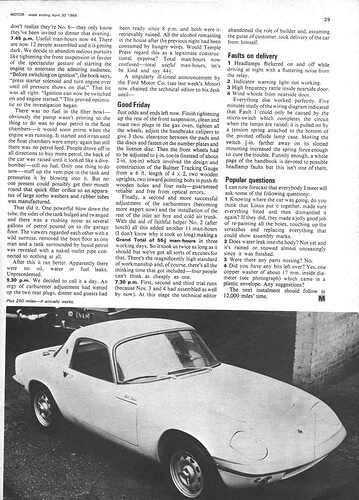

- Did you have any bits left over? Yes, one copper washer of about 17 mm. inside diameter (see photograph) which came in a plastic envelope. Any suggestion?

The next instalment should follow in 12,000 miles’ time.